Project Description

I have a DIY 3D printer which I am updating and modifying for about 4 years now. Originally it was a Voron 1.6 model but over the course of time I modeled my own parts and at this point it did depart quite a bit from here. This project is about doing further redesign and improvements in general. There are couple of tasks I can pick from and I will do so depending whether I feel like 3D modelling or digging into software side of things.

Goal for this Hackweek

Choice A: Redesigning printing head (probably XY axis as well) * current one seems to be producing artifacts due to instability * has exposed connectors

- New printing head will have:

- 2 linear rails instead of one

- 2 40mm radial part cooling fans

- Omron TL-Q5MC2 inductive probe

- Dragon hotend

- hotend cooling - probably 30mm fan due to space constraints

Horizontal X might be an interesting concept to try

Choice B: klipper monitoring using grafana/influxDB/telegraf

- research telegraf/influxDB/grafana setup for monitoring

- collect general data from Raspberry Pi controller

- collect printer data from Klipper

Choice C: LCD screen and Raspberry pi case

- Raspberry and LCD are mounted together

- currently there is no case for them, only a frame

- case should have ideally a small fan for better cooling

Final Result

CAD models:

- Front view: https://github.com/lpalovsky/Dragon-3d-printer/blob/main/img/frontview.png?raw=true

- Side view: https://github.com/lpalovsky/Dragon-3d-printer/blob/main/img/sideview.png?raw=true

- X-axis: https://github.com/lpalovsky/Dragon-3d-printer/blob/main/img/Xaxis.png?raw=true

- Cross section - side: https://github.com/lpalovsky/Dragon-3d-printer/blob/main/img/Modelcrosssection.png?raw=true

- Cross section - front: https://github.com/lpalovsky/Dragon-3d-printer/blob/main/img/Crosssection_front.png?raw=true

Photo and video: - 3D printer: https://github.com/lpalovsky/Dragon-3d-printer/blob/main/img/Printer.jpeg?raw=true - Toolhead closeup: https://github.com/lpalovsky/Dragon-3d-printer/blob/main/img/Toolhead.png?raw=true - Short video: https://cdn.artstation.com/p/video_sources/001/646/134/img-0860.mp4

Comments

-

-

about 2 years ago by lpalovsky | Reply

I ended up working on option A: Redesigning printing head (probably XY axis as well)

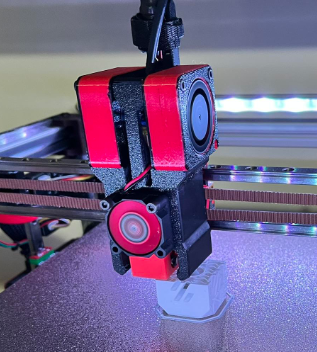

New toolhead has all the components I wanted:

- 2x Radial blower part cooling fan

- Dragon hotend

- 30mm hotend cooling fan

- Omron TL-Q5MC2 inductive probeAdditionally I purchased TMC2209 stepper drivers and enabled sensorless homing which allow homing without using endstop switches. I had to as well remodel X-axis joints because previous ones used only one linear rail.

Parts were modeled in Autodesk Fusion 360 and printed on original printer - yes, printer was printing itself!

Disclosure: Models for components like fans, screws, hotend... etc were not mine, but taken from grabcad library. I designed only body which holds all components together (grey, red and black parts :D)

-

Similar Projects

This project is one of its kind!